This model has superseded the Series 100

Noise Reduction: January 2023 Test Data:

| Octave band centre frequencies (Hz) | |||||||

| Model | 125 | 250 | 500 | 1000 | 2000 | 4000 | |

| Series 125S | 13 | 13 | 15 | 20 | 23 | 23 | dB |

| Series 125 | 14 | 14 | 16 | 21 | 27 | 27 | dB |

Noise Reduction: October 2023 Test Data:

| Octave band centre frequencies (Hz) | |||||||

| Model | 125 | 250 | 500 | 1000 | 2000 | 4000 | |

| Series 200S | 14 | 12 | 16 | 23 | 23 | 18 | dB |

| Series 200 | 14 | 13 | 17 | 27 | 30 | 22 | dB |

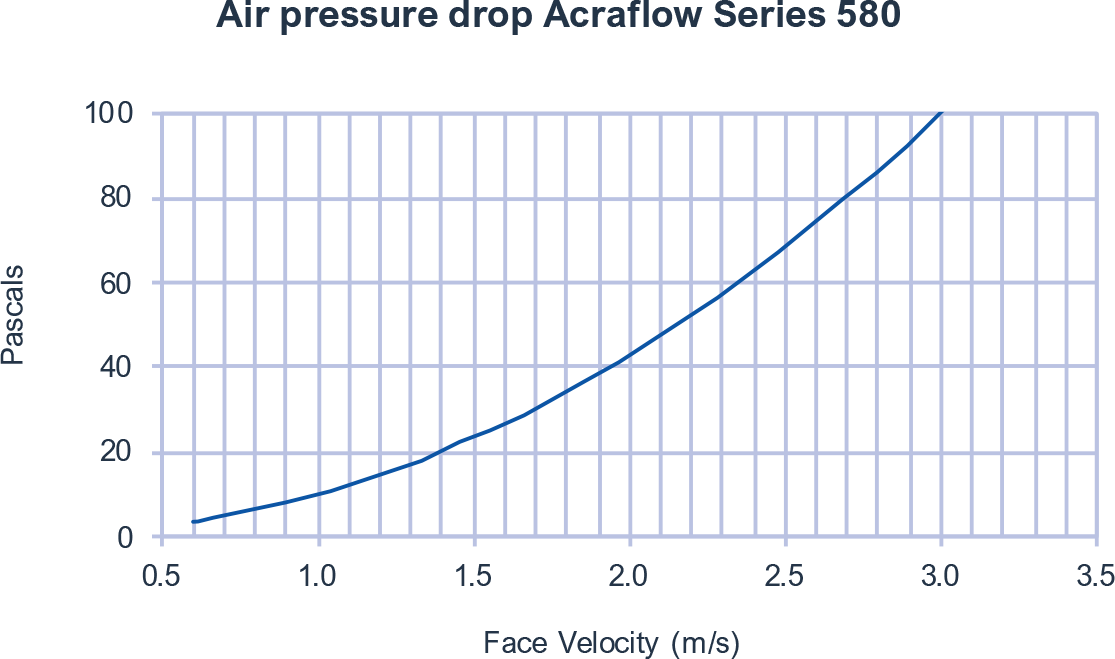

The Series 580 models have superseded the Series 600

Noise Reduction: July 2020 and July 2022 Test Data:

| Octave band centre frequencies (Hz) | |||||||

| Model | 125 | 250 | 500 | 1000 | 2000 | 4000 | |

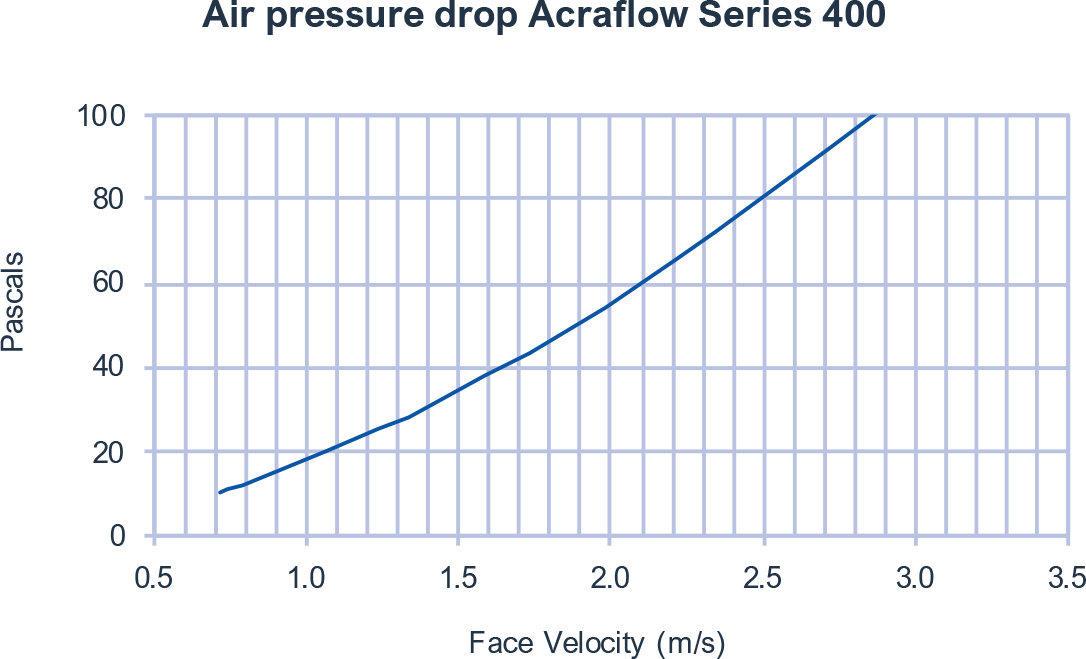

| Series 400 | 15 | 20 | 25 | 27 | 30 | 30 | dB |

| Series 580/16 | 15 | 20 | 32 | 37 | 32 | 32 | dB |

| Series 580/20 | 16 | 22 | 27 | 34 | 36 | 33 | dB |

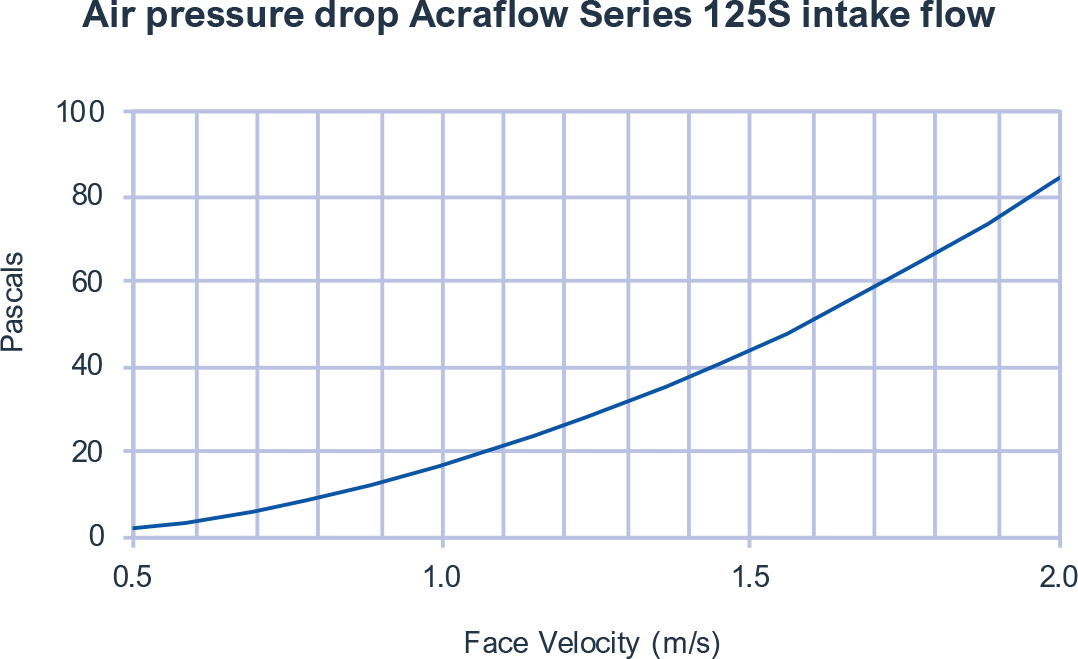

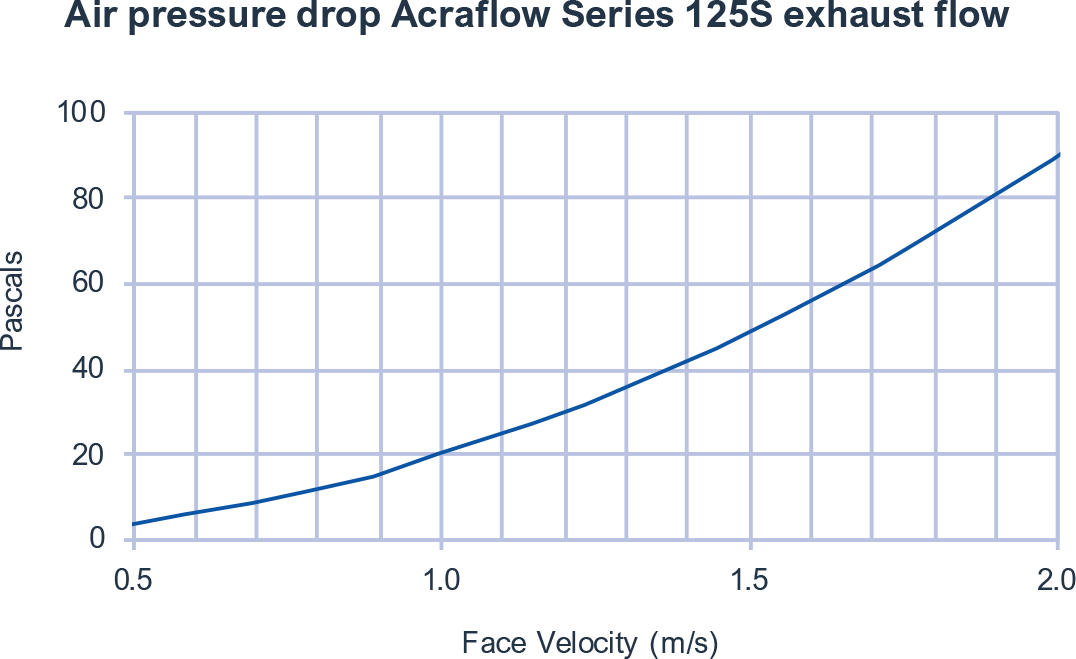

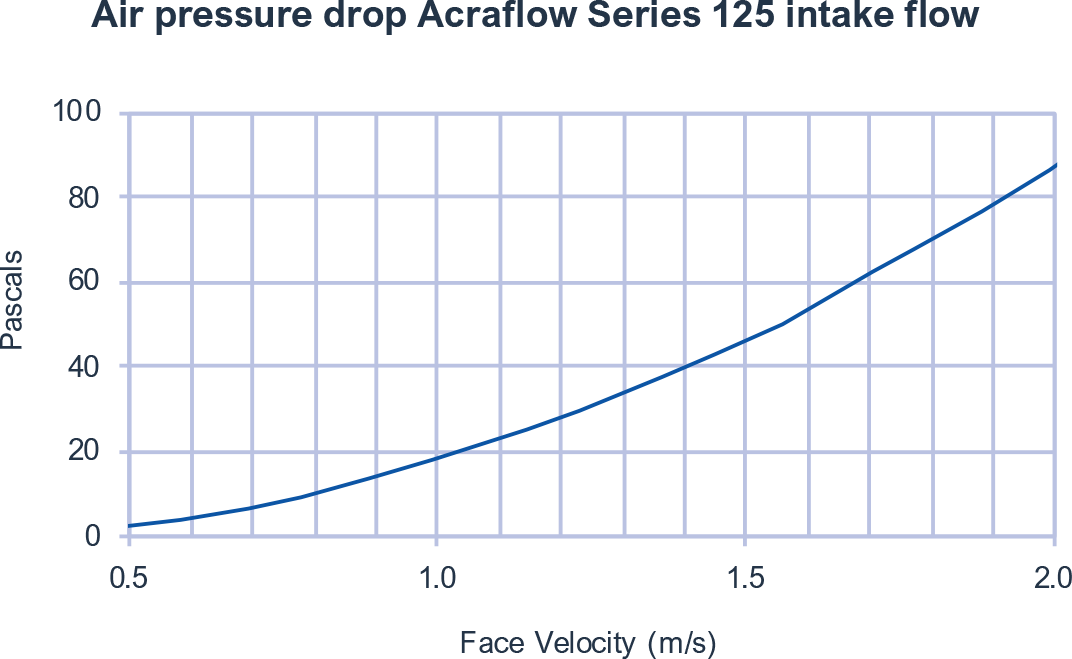

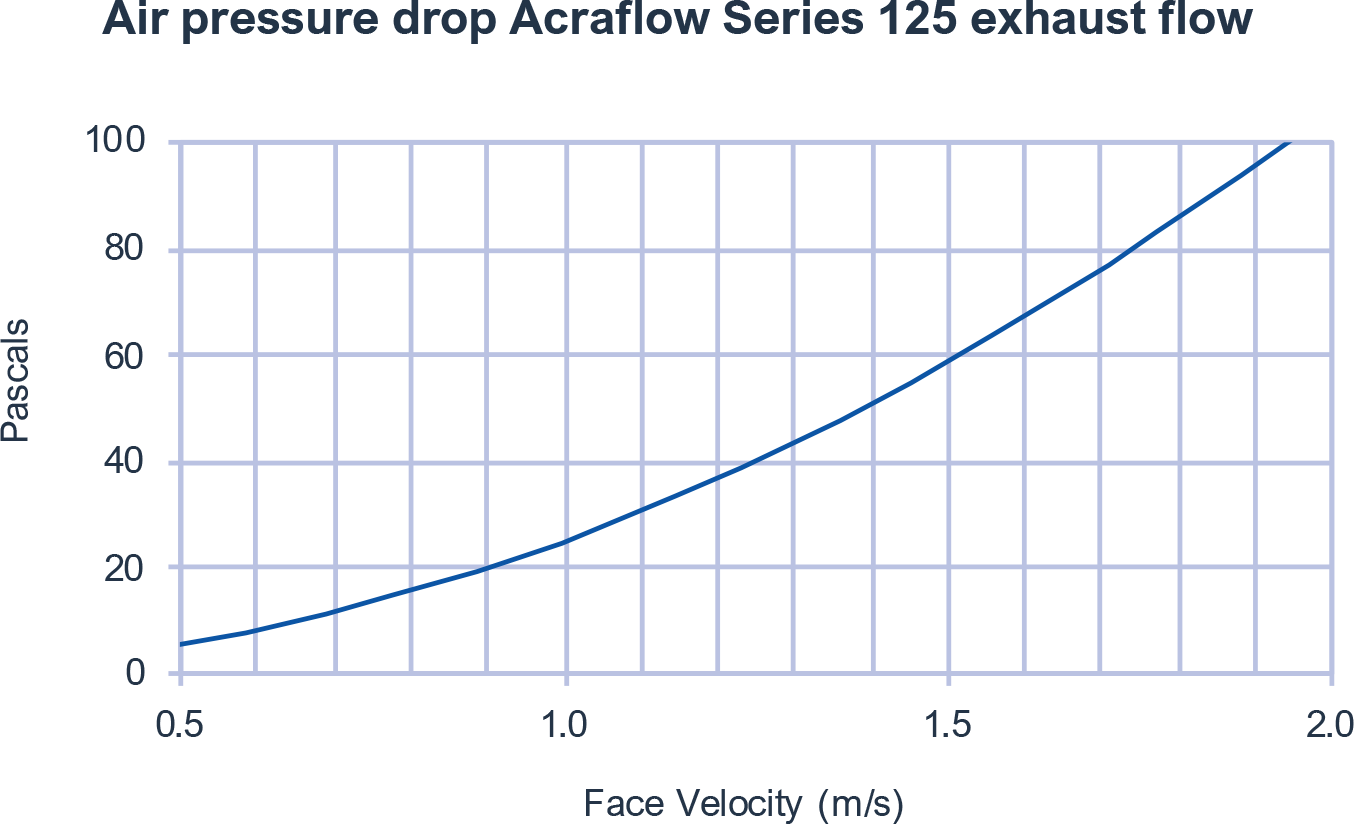

Series 125 product sheet

Series 200 product sheet

Series 400 product sheet

Series 580 product sheet

We have data available for over ten standard models. For more information please contact our office by phone or email.

Acoustic louvres use and care instructions

Weather louvres use and care instructions